The luxury car-level experience, what makes Defond DMB micro switch great?

The reason luxury cars are scrutinized comes pursuing excellence in every aspect. Even a small switch in the car must be carefully selected.

on The feedback the driver receives from pressing switches is the signal the car is ready. Therefore, the feeling of the switch is particularly important affecting theoverall experience and is also an important part of the quality of the vehicle.

Defond DMB is widely used in luxury cars. It combines strength, travel and control, bringing the ultimate experience.

How is the feel of a switch defined? How to ensure the consistency of switch feel?

Generally, it comes from the proportional relationship between the operating force and the operating stroke in the stroke curve.

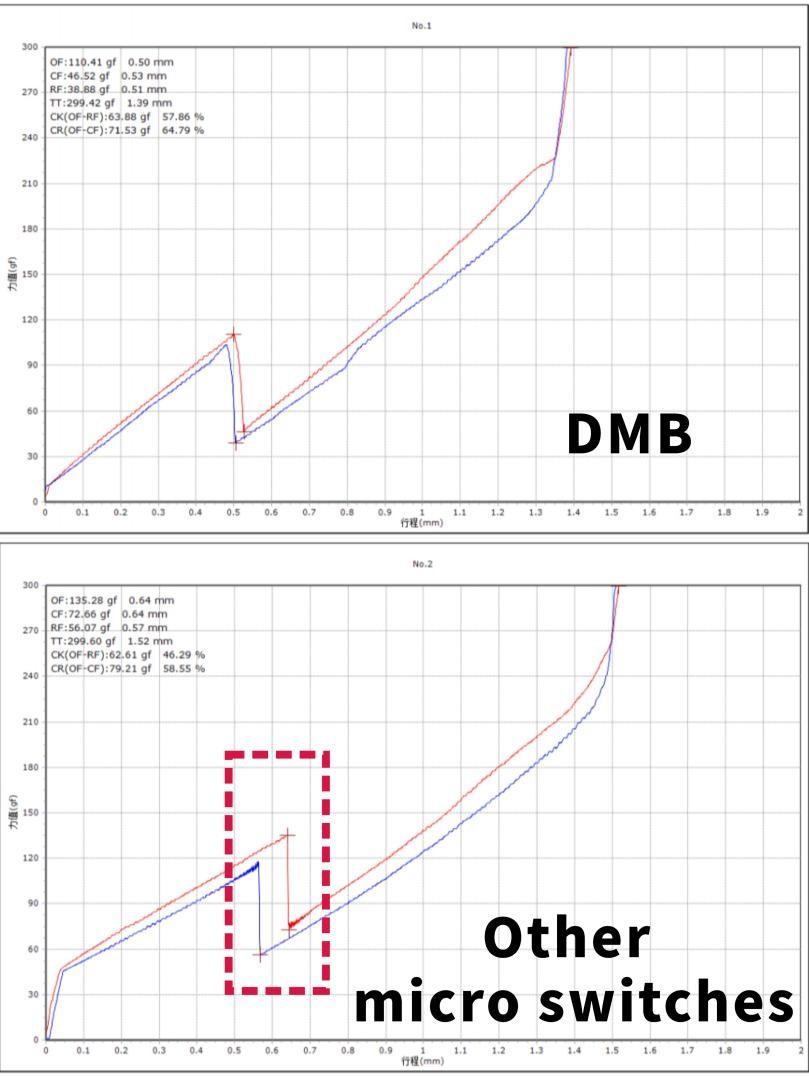

Tactile curve comparison between DMB and other micro switches

*The red line is the downward pressure, and the blue line is the rebound curve

(sampling test)

Data comparison:

|

Data |

DMB |

other micro switches |

|

OF(gf) |

110.41 |

135.28 |

|

CF(gf) |

46.52 |

72.66 |

|

CR=(OF-CF)/OF*100% |

64.79% |

58.55% |

|

PT(mm) |

0.5 |

0.64 |

|

MD(mm) |

0.01 |

0.07 |

From comparison DMB has a shorter stroke, lighter operating force, smaller differential stroke and more sensitive response.

The CR value is also better than competing products, the pressure change is more linear, and the overall feel is better. (Competing products have a sharp increase in the preload pressure when the stroke is 0-0.05mm)

Data, high-quality raw materials, professional structural design and lean production are the required core components to ensure the ultimate feel in addition to stable and consistent quality.

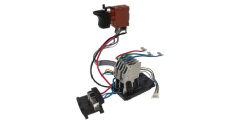

Strict selection of materials, high reliability

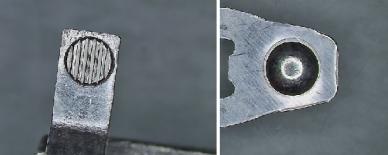

①Imported beryllium copper

DMB utilize imported beryllium copper sheet, which has high relaxation resistance and excellent wear resistance.

②Silver alloy contacts

DMB uses silver alloy contacts, which have good oxidation resistance, small and stable contact resistance (gold contacts are also available).

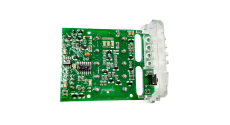

Precisely made and strict quality control ensures a stable and consistent feel

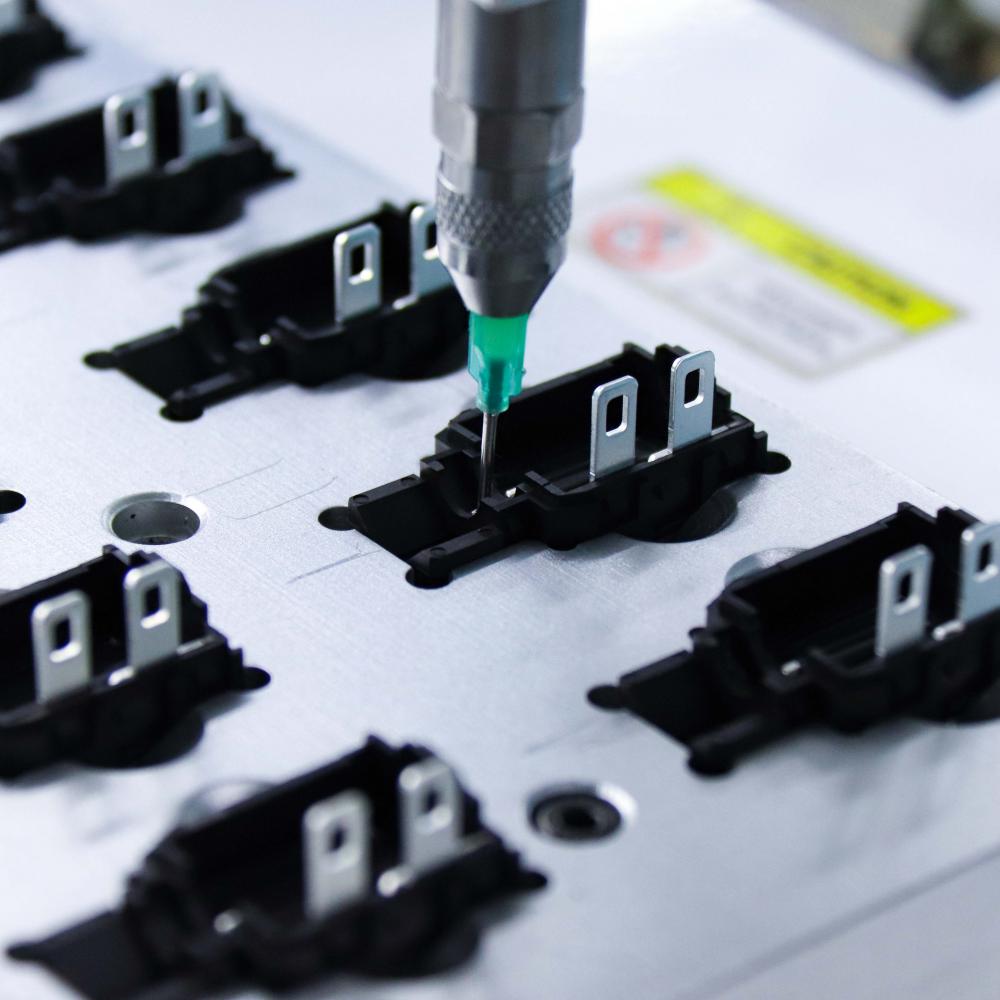

①Mold

Strictly controlled from the mold opening stage, the core components are integrally formed and the mold tolerance is less than or equal to 0.03mm.

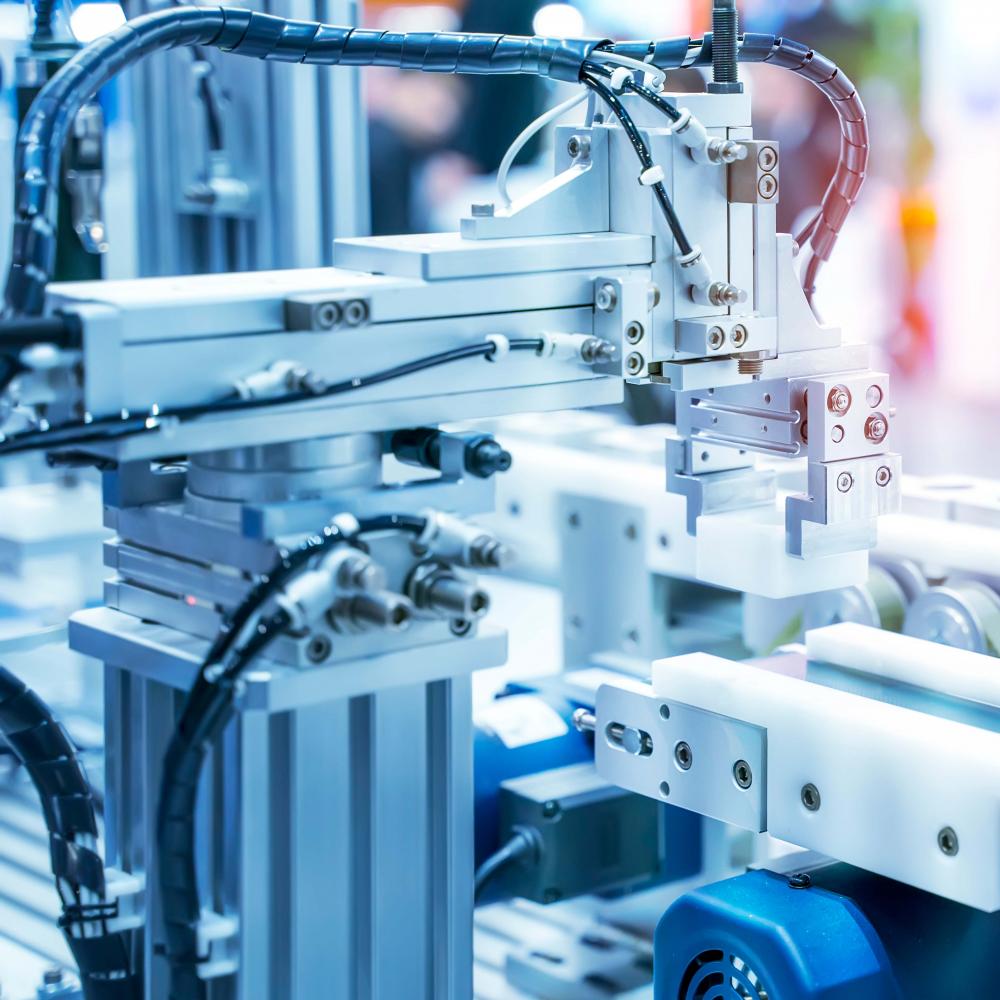

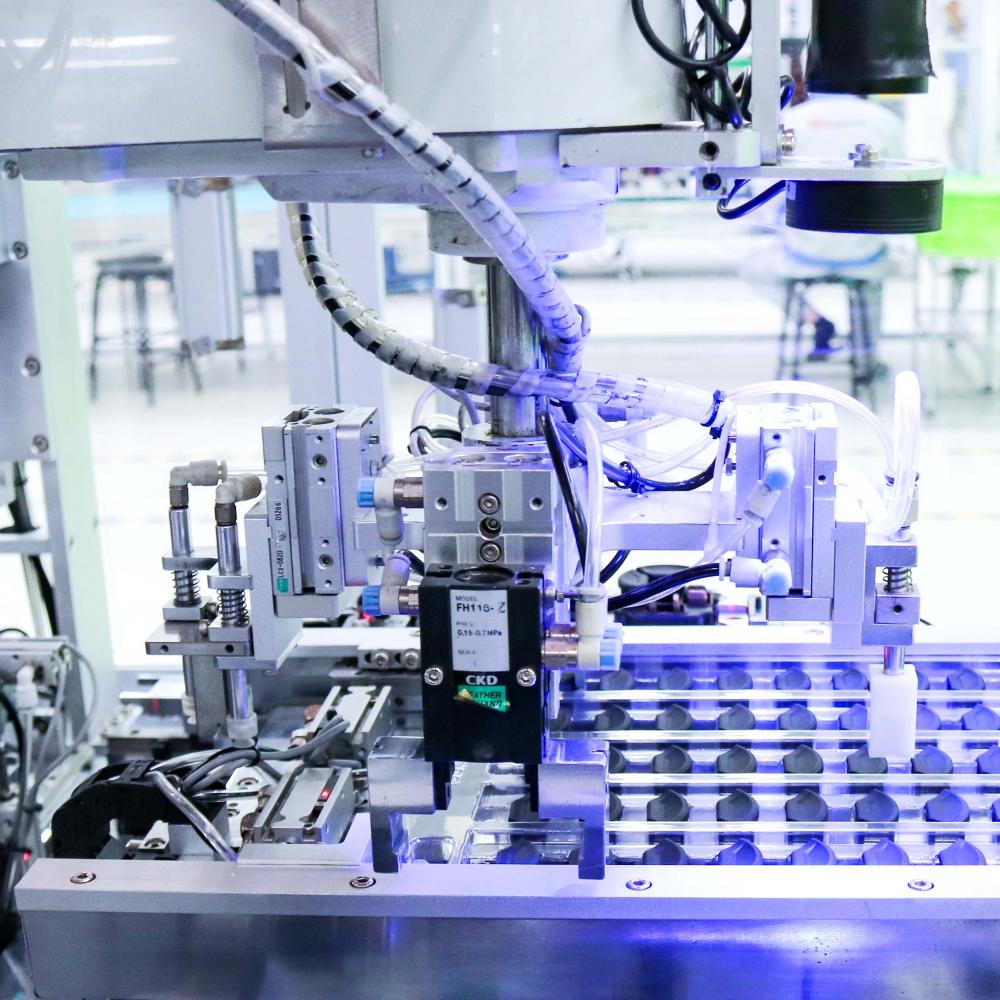

②Digital intelligent production

High degree of automation, the raw materials are cleaned by ultrasonic waves and the production environment is clean and dust-free. Each link is strictly controlled through data monitoring. There are more than 20 kinds of data monitoring in the whole process. Accuracy ±1gf, to ensure a stable and consistent feel.

Customized service: a variety of structures and loads are optional

DMB can provide a variety of drive rod designs, which can be structurally adjusted according to the end products, be customized to carry a variety of loads, with optional NO, NC or NO+NC circuits.

Specification:

|

Size |

20mm*10.6mm*6.5mm |

|

OF |

120gf±10gf |

|

Protection Level |

IP30 |

|

Insulation Resistance |

≥50MΩ |

|

Contact Resistance |

≤50mΩ |

|

Certification |

UL,CSA,CQC、ENEC |

Typical Appliance